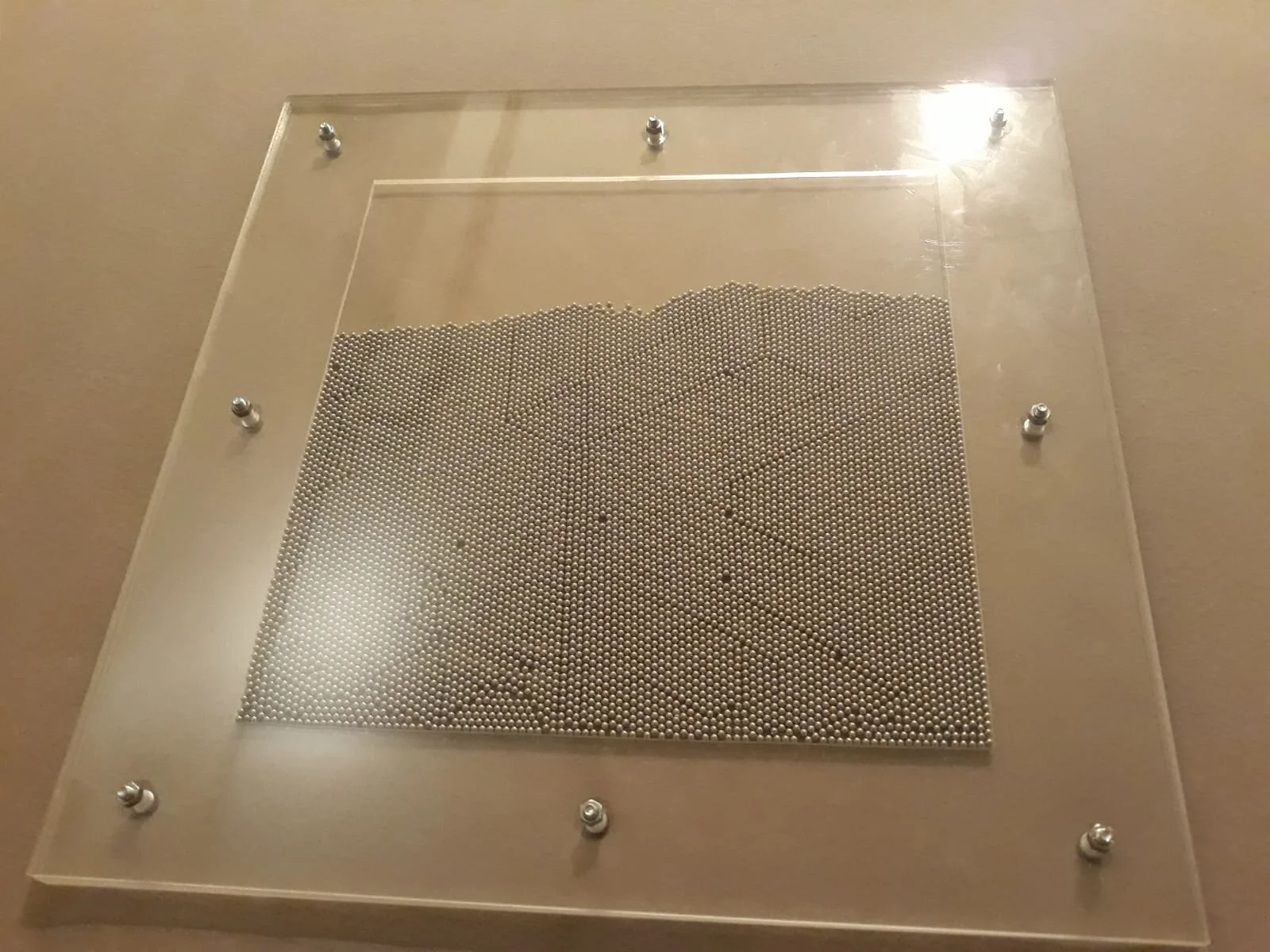

Acrylic frame for visualisation of crystalline structures in metals

What makes this so interesting?

The ball bearings in this frame build shapes which very closely resemble metallic structures with crystalline defects. For context: Metals have different lattices (arrangement of atoms) and build crystalline structures. These crystalline structures would be perfectly arranged and flawlessly repeating over all three dimensional axes (after all, this is what defines a crystal), if they wouldn’t exist in an imperfect world: Every crystalline structure and therefore metals as well, have defects and irregularities which break the pattern. These defects can show in multiple ways, as demonstrated so visually by the ball bearings (atoms). See the little spots where the atoms are missing? These are called point defects (or zero dimensional-defects), since only one atom is missing. You can also see straight lines, where the atoms are not stacked as they should be: These are line defects (or one dimensional defects). But perhaps the most interesting (and obvious) defects are the two dimensional defects, typically called grain boundaries. You can see where some of the atoms build little “islands” which corner on each other and usually have a different alignment. These grains can have different sizes, resulting in different mechanical properties of the metal.

This model can also be correlated to the heat treatment of metals: Shaking the atoms (aka heating up the material) results in a different formation of the crystal, if you shake it hard enough. Also: “Vibrating “ the atoms carefully (as in: controlled heating and cooling of the metal) results in a much more homogenous crystal. This is called “normalising” and results in a material that is usually softer and with less internal stress (maybe we all should try normalising for a while!). See the following pictures: The first one is a typical structure you would get from this frame and the second one is shot after me carefully shaking it for a bit.

The structure pre-shaking

After a bit of shaking, the structure has a lot less defects!

How I made this frame

This easy-to-make frame consists of three layers of acrylic, sandwiched together using screws. The outside layers are 5mm thick, so bending is minimal. This is actually quite critical since the weight of several hundreds of steel ball bearings can bend thinner acrylic quite easily. In the first version I used 2mm sheets and, lets just say, I needed to pick up a lot of ball bearings after the first shake. The ball bearings are 3mm in diameter, which is a perfect size for this display in my opinion. The frame is 40x40cm (display area 28x28cm) and is relatively heavy, so a good mounting solution is required if you want to hang this.

Some quick tips: When making this frame, only peel off the protective sheet immediately before assembly. I know its hard to resist, but scratches are ugly and a real possibility with a material this soft! Also, try to keep your pets away when assembling, because the static electricity of the freshly “peeled” acrylic attracts a lot of hairs, which can be quite an eyesore. Lastly, tight screw connections will prevent you from ball bearings in you carpet, but remember: acrylic might suddenly crack if you overdo it! Of course, some transparent acrylic glue might be an alternative.

All in all, this was a very interesting short project, which I absolutely would recommend making if you like this kind of “nerdy” stuff!