Simple 532nm DPSS Laser

In the following few paragraphs, I show you how I made a simple diode pumped solid state (DPSS) green laser module with active TEM cooling. Even though I used my CNC-Router and SLA-Printer, in theory, nothing of the sort is necessary. In fact, both the crystal and the pump diode are quite cheap on sites like eBay.

Since the module was built for calibrating a spectroscope, it’s output power is quite limited. It is, essentially, a green DPSS laserpointer.

How does it work?

The lasing medium of this laser is a neodymium doted vanadate crystal (Nd:YVO4). Because the laseractive ions, the Nd3+ Ions, are the same as in Nd:YAG lasers, their emission wavelength are essentially the same at around 1064nm. This puts it in the infrared spectrum, so it is not visible to the human eye.

Pumping the laser medium

Before we get into how the infrared laser emission is turned into visible light, we should shortly discuss how the medium is pumped. Looking at the absorption spectrum of the Nd:YVO4 crystal, we can see, that the pump-wavelength should be around 808nm:

At this wavelength, the absorption of the material is highest. Also, we can see that the peak emission is around 1064nm, which is what we would expect. Because 808nm laser diodes exist and are highly available even for hobbyists even at higher powers, pumping the crystal is no problem.

Intracavity frequency doubling

In order to make the laser emission visible, it needs to be frequency doubled. Because the wavelength of light (as with any periodic wave) is inversely proportional to its frequency, doubling the frequency means dividing its wavelength by 2. This results in a wavelength of 532nm. This frequency doubling effect can only occur in crystals which show nonlinear optical behaviour, for example potassium titanyl phosphate (KTP). With these crystals, it is possible to convert an invisible infrared beam into a visible green output. The crystal itself may be seated outside (extracavity doubling) or inside the resonator (intracavity doubling). Since the doubling efficiency is dependent on the input power of the base frequency, higher powers lead to higher conversion efficiency. Since we are dealing with relatively low power laser diodes (~500mW), this is a real problem. Because the field intensity inside a laser resonator is much bigger than outside, intracavity doubling is desirable. Below you can see a schematic of a typical linear intracavity doubled resonator:

In this project I used a composite crystal, consisting of the Nd:YVO4 and the KTP crystals optically bonded together. This already is quite convenient, but since the end faces of the composite crystal are coated to form the correct mirrors, this module essentially only lacks the pump diode for operation.

The setup in principle

The laser diode, powered by the correct laser diode driver circuit, is collimated and then focussed into the middle of the Nd:YVO4 crystal. In order to get a high powerdensity, a lens with a short focal length is required, in this case f=10mm. The schematic of the setup is shown in the picture below.

Since the doubling efficiency of the KTP also depends on the pump polarisation, it is necessary to rotate the diode with respect to the crystal in order to find the optimal roll (rotational angle) of the diode. In this case, a laserdiode with about 500mW of optical output power was used.

The physical setup

Picture of the module without the protective case.

The physical setup was designed with three main goals in mind: long-term operation, adjustability and compactness.

In order to enable long-term operation (>1min cw) of the laser module, it needs to be actively cooled. This is done via a Thermo-Electric-Cooler (TEC) which is essentially a plate that can create a hot and a cool side as soon as current flows through it. If the hot side is mounted on a heat sink (in this case a big aluminium block), the cool side can be used to cool the laser diode. This keeps it from overheating. The laserdiode housing is mounted on the TEC using thermal glue.

This module allows fine tuning of the crystal orientation with respect to the pump diode using some M3 screws. Although this orientation is not as critical as adjustments in the laser world usually are, the optical axis of the crystal should be aligned fairly well to the laser diode. One result of a slight misalignment can be a TEM10 mode of the output beam:

Due to a misalignment in the prototype, it created a beam with a split shape: A TEM10 mode.

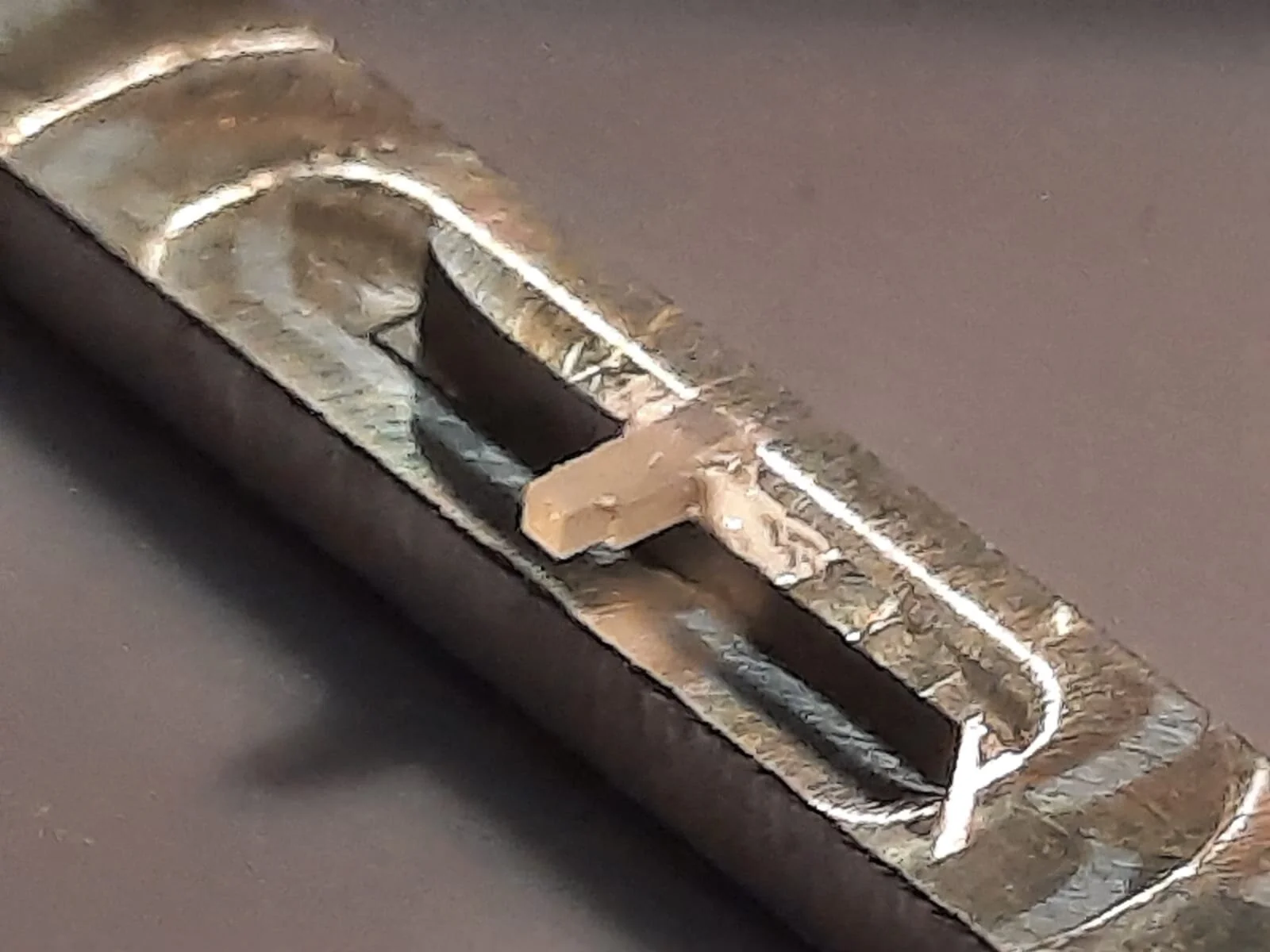

Another small peculiarity of this module is how I mounted the crystal:

As you can see (forgive the low resolution, this is zoomed in really far), it is mounted so that only the Vanadate is touching the aluminium. This enables passive cooling of the gain medium but also allows the KTP to warm up a bit, increasing its doubling efficiency.

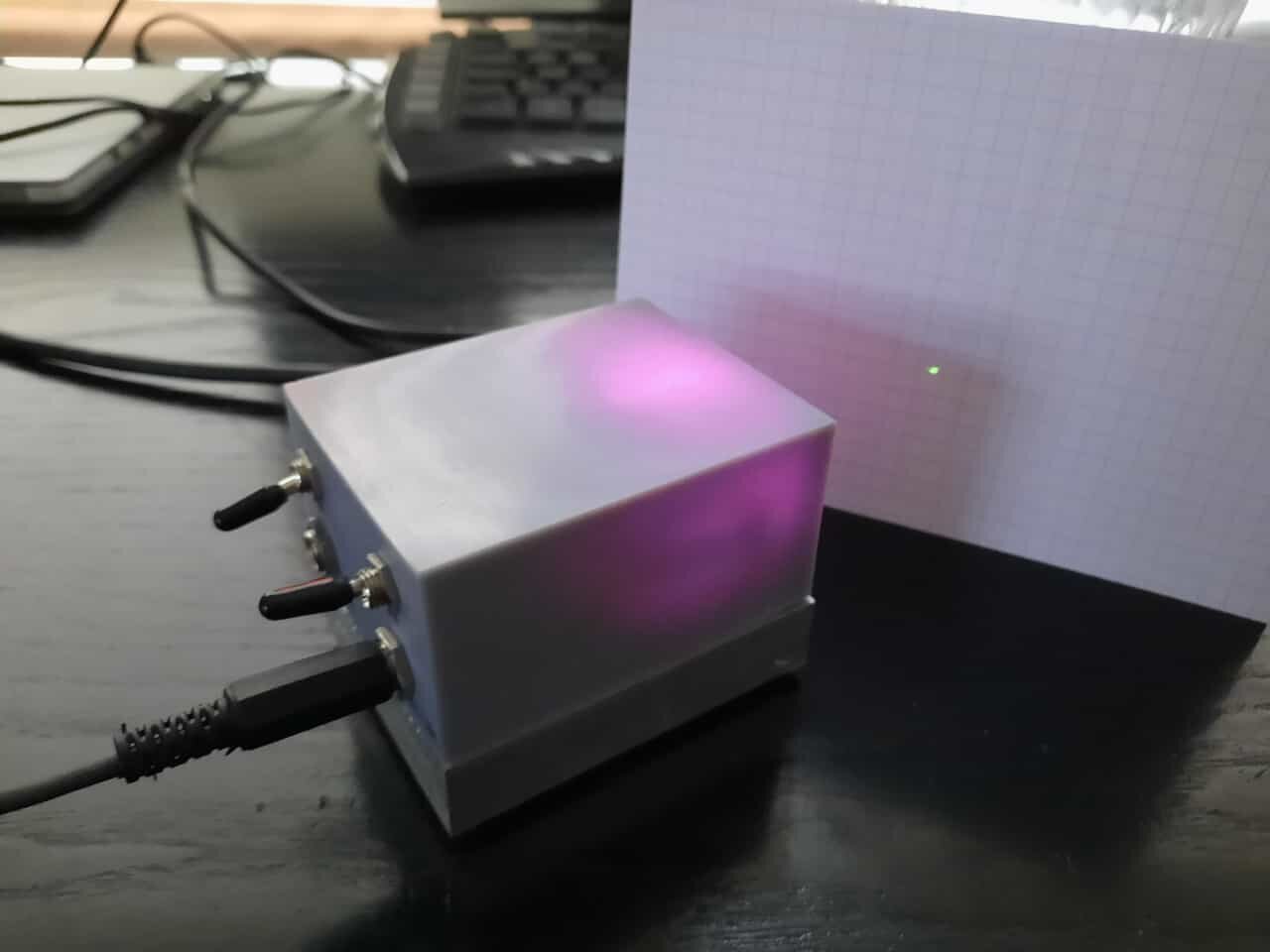

The whole module is protected by a casing (SLA-printed) that is supposed to make it air-tight so that no dust can get onto the crystal faces. The output window of the module consists of two IR-filters usually sold for M12-CCTV cameras. This prevents the IR-pump beam from leaving the module and makes it eye-safe.

Furthermore, on the back of the case are two power jacks and corresponding switches: One for powering the diode driver and therefore the laser (a normal 5V power supply is enough for this) and one for enabling the thermoelectric cooling.

This is the whole module assembled and ready to be closed up.

And this is about it! It certainly would be able to make this module even more compact, there are, after all, laser pointers using exactly this principle. These are, however not able to be thermoelectrically cooled. Also, they are aligned using precision equipment that hobbyist usually do not have access to. Although it would be possible to improve on this design, it definitely will do the job of the creating a set wavelength for calibrating a homemade spectroscope.

Thank you so much for reading this! I hope to see you next time.

~N